Cold Storage Facilities

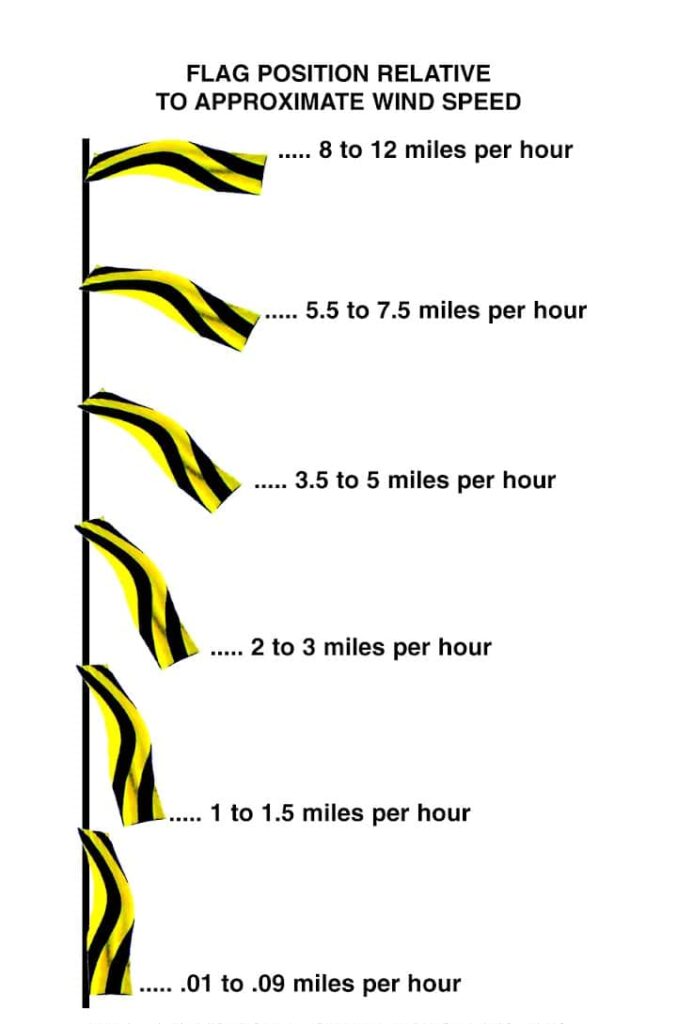

Wind Tracker™ Windsocks serve as crucial tools at cold storage facilities, specifically in the context of an ammonia leak or emergency evacuation. As per OSHA (Occupational Safety and Health Administration) requirements, windsocks are mandated to be installed to assess wind direction during an ammonia leak incident or emergency evacuation. This is crucial to ensure the safety of personnel and the surrounding environment.

Wind Direction Assessment:

Wind Tracker™ Windsocks provide vital information about wind direction during an ammonia leak or emergency evacuation scenario. Ammonia is a hazardous substance commonly used in refrigeration systems at cold storage facilities. In the event of a leak, understanding wind direction is critical for determining the dispersion pattern of the ammonia gas. Windsocks allow personnel to quickly assess wind direction and adjust evacuation routes and assembly areas accordingly. This helps ensure that evacuees move in a direction that minimizes their exposure to the toxic gas.

Emergency Response Planning:

Wind Tracker™ Windsocks are integral to emergency response planning for ammonia leaks. By monitoring wind direction using windsocks, facility operators and emergency response teams can assess the potential spread of ammonia vapors. This information helps in establishing safe evacuation routes, determining assembly points, and implementing other emergency response measures. Windsocks aid in identifying areas downwind where the gas may pose a risk, allowing personnel to avoid those areas during the evacuation process.

Regulatory Compliance:

Wind Tracker™ Windsock installation and usage as part of emergency evacuation procedures for ammonia leaks align with OSHA regulations and requirements. OSHA mandates that facilities handling hazardous substances like ammonia must have comprehensive emergency response plans in place. These plans include provisions for assessing wind direction during evacuations to minimize the risk of exposure to toxic gases. By adhering to these regulations, cold storage facilities demonstrate their commitment to employee safety and compliance with OSHA standards.

Effective Communication:

Wind Tracker™ Windsocks serve as visual indicators that facilitate effective communication during an emergency situation. They provide clear and easily identifiable information about wind direction to all personnel at the facility. This helps in guiding evacuees, emergency responders, and other personnel to safety and aids in the overall coordination of the evacuation process. Windsocks also assist emergency personnel in relaying real-time information to each other, enabling them to adjust response strategies based on wind conditions.

Wind Tracker™ windsocks are a necessary tool at cold storage facilities as an OSHA requirement for ammonia leak and emergency evacuation situations. They play a critical role in assessing wind direction during an ammonia leak incident, aiding in emergency response planning, complying with regulatory requirements, and facilitating effective communication. By installing windsocks and incorporating them into their emergency procedures, cold storage facilities can enhance employee safety, minimize exposure risks, and ensure compliance with OSHA regulations.