Hazardous Material Storage

Wind Tracker™ Windsocks serve as critical tools in the storage of hazardous materials to assess and monitor wind conditions, specifically wind direction, in order to prevent the dispersion and potential risks associated with these substances. They provide valuable visual indicators that aid in determining the suitability of storage locations and implementing appropriate safety measures.

Wind Dispersion Assessment:

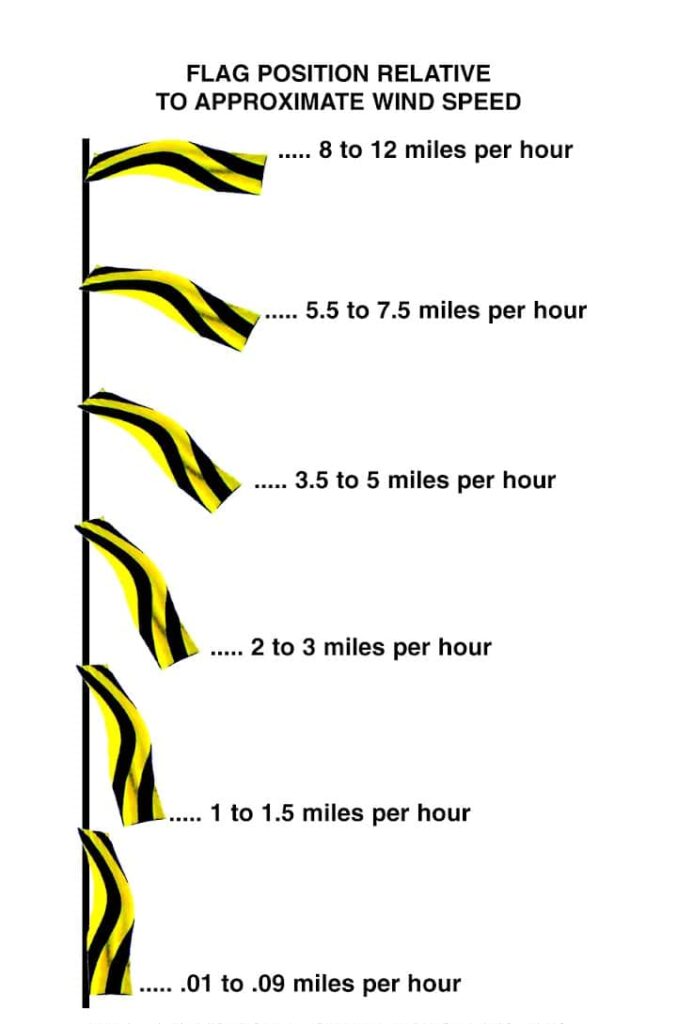

Wind Tracker™ Windsocks assist in assessing the potential dispersion of hazardous materials. By monitoring the windsock, personnel can determine the prevailing wind direction in real-time. This information is crucial for evaluating the likelihood of hazardous materials being carried away from their storage area. It helps in identifying areas downwind where the dispersion of harmful substances may pose a risk to human health, the environment, or nearby infrastructure.

Ventilation System Control:

Proper ventilation is critical when storing hazardous materials to prevent the accumulation of potentially dangerous fumes or gases. Wind Tracker™ Windsocks aid in assessing the effectiveness of ventilation systems by providing information on wind direction. By understanding the prevailing wind pattern, operators can strategically position ventilation outlets to ensure that any released gases or vapors are efficiently directed away from occupied areas and towards safe dispersal points.

Emergency Response Planning:

Wind Tracker™ Windsocks play a vital role in emergency response planning for incidents involving hazardous materials. By monitoring wind direction, emergency responders can quickly determine the areas that may be affected by hazardous material releases. This information allows for the efficient implementation of evacuation plans, establishment of exclusion zones, and deployment of resources in a manner that minimizes exposure risks and maximizes the safety of personnel and the surrounding community.

Site Selection:

When choosing a storage location for hazardous materials, wind conditions are a critical consideration. Wind Tracker™ Windsocks help in the assessment of potential storage sites by providing information on local wind patterns. This allows operators to identify areas with wind conditions that minimize the risks associated with hazardous material storage. Selecting sites with Wind Tracker™ windsocks strategically positioned to assess wind patterns ensures that storage facilities are located in areas where dispersion risks are minimized, protecting both the environment and human safety.

Wind Tracker™ Windsocks are essential tools in the storage of hazardous materials as they assist in assessing wind dispersion, controlling ventilation systems, facilitating emergency response planning, aiding in site selection, and supporting ongoing maintenance and monitoring efforts. By utilizing Wind Tracker™ windsocks, operators can proactively manage the risks associated with hazardous materials, promote safety, and minimize the potential for environmental contamination or harm to personnel.