Oil Fields

Wind Tracker™ windsocks serve as essential tools at oil fields, providing crucial information about wind conditions to ensure the safety of personnel, equipment, and operations within these complex industrial environments. The unique challenges of oil field operations, which involve various hazardous activities and equipment, make windsocks invaluable for maintaining safe and efficient practices.

Hazardous Gas Dispersion:

Oil fields often involve the extraction and transportation of hydrocarbons, which can release hazardous gases such as hydrogen sulfide (H2S). In the event of a gas leak or release, windsocks play a critical role in assessing wind direction. By monitoring the windsock, oil field operators can quickly determine the prevailing wind direction at ground level. This information is essential for predicting the potential movement of hazardous gases, enabling quick response and the implementation of safety measures to protect personnel and mitigate risks.

Emergency Response Planning:

Wind Tracker™ windsocks are integral to emergency response planning at oil fields. In the event of accidents, gas leaks, or fires, windsocks provide real-time data on wind direction to emergency response teams. This information helps in developing effective evacuation plans, establishing assembly areas, and determining response strategies to minimize the impact of the emergency on personnel and nearby communities.

Flare Stack Monitoring:

Oil fields often use flare stacks to burn off excess gases and emissions. Wind Tracker™ windsocks assist in monitoring wind direction to ensure that the combustion products are safely carried away from personnel and equipment. Proper monitoring prevents the risk of gas and emissions being blown back towards the oil field, reducing potential safety hazards.

Dust and Debris Management:

Wind Tracker™ windsocks aid in managing dust and debris in oil fields, which can be generated by machinery, vehicles, or drilling activities. Monitoring wind direction helps operators predict the movement of dust and debris, allowing them to implement preventive measures such as water spraying or dust suppressants to mitigate airborne particulates and maintain air quality.

Crane and Rig Operations:

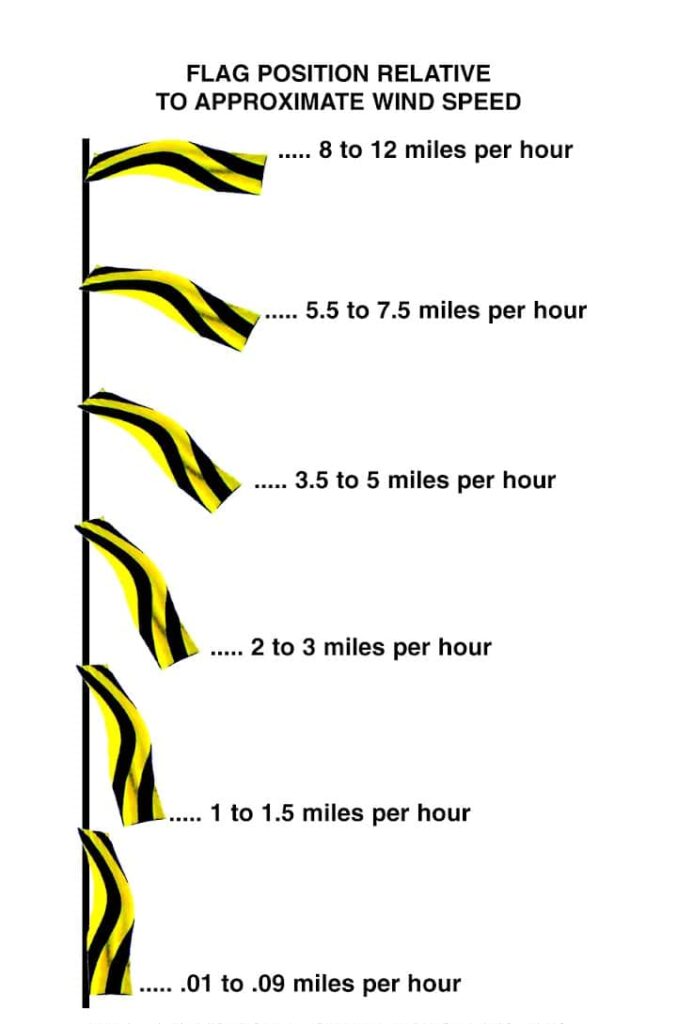

Wind Tracker™ windsocks provide critical information for safe crane and rig operations. Wind conditions can impact the stability of cranes and drilling rigs, affecting safety and efficiency. By observing windsocks, operators can assess whether wind speeds are within safe limits for lifting operations and decide whether to proceed, delay, or adjust procedures accordingly.

Equipment Maintenance:

Wind Tracker™ windsocks assist in ensuring safe equipment maintenance activities in oil fields. By continuously monitoring wind direction, operators and maintenance personnel can assess whether wind conditions are safe for tasks such as working at heights, conducting repairs, or handling heavy equipment. Windsocks provide valuable information for maintaining safe work conditions and preventing accidents.

Wind Tracker™ windsocks are a necessary tool at oil fields due to their role in assessing wind direction, managing hazardous gas dispersion, supporting emergency response planning, monitoring flare stack emissions, managing dust and debris, and enhancing safety during equipment operations and maintenance. By utilizing windsocks, oil field operators can enhance safety measures, mitigate risks, and optimize the safety and efficiency of their operations within these challenging industrial environments.