Wind Tracker Product Sheet

Wind Tracker™ Wind Detection System

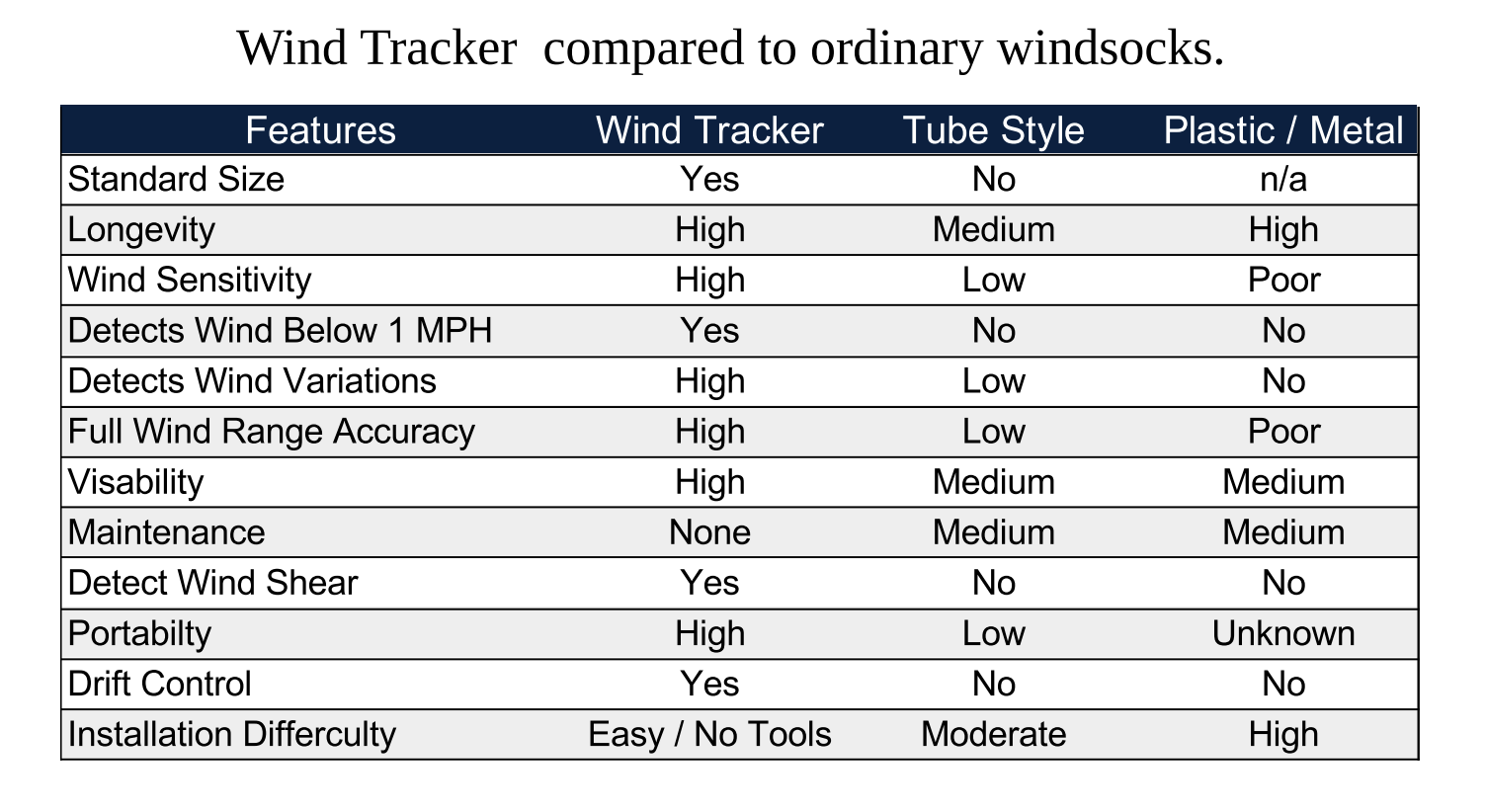

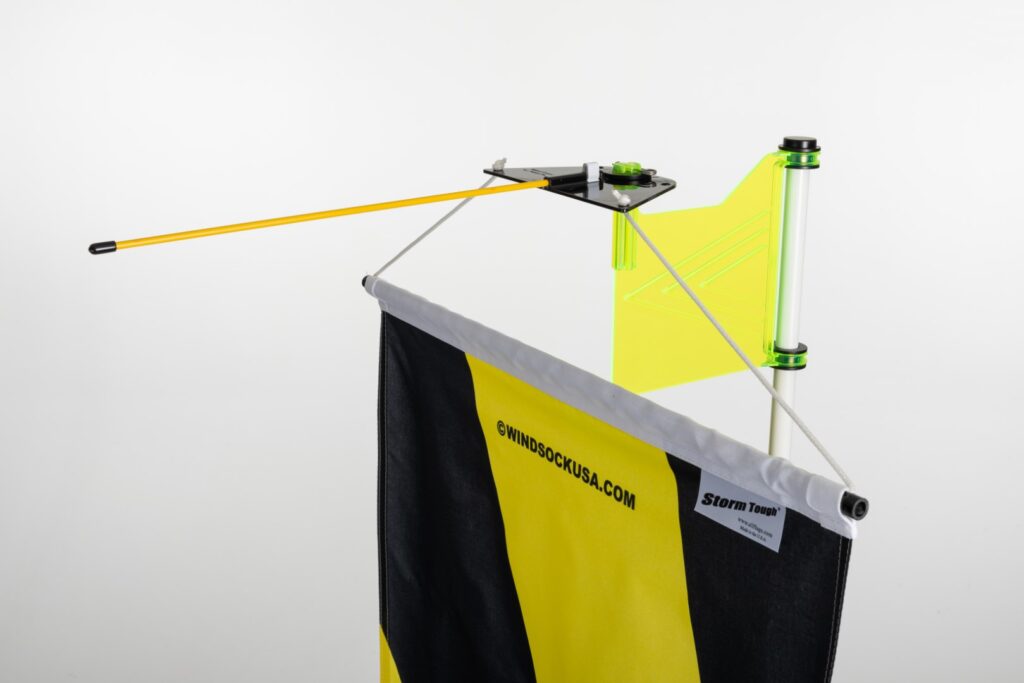

Designed for on-site and in-ground portable applications. High impact Lexan® construction. The DV9001 and Patented Pivotal Harness Plate provide 360 degrees of rotation around the Wonder Pole® at any wind speed. The Wind Tracker™ windsock is attached to the pivotal harness plate with two 1000-pound test braided polyester cords. Our “flip-over” rod is designed to prevent the windsock flag from getting tangled or hung up on the pole.

Designed for rapid deployment on or off site. The Wind Tracker™ is Made in the USA and guaranteed to outperform conventional tube type windsocks.

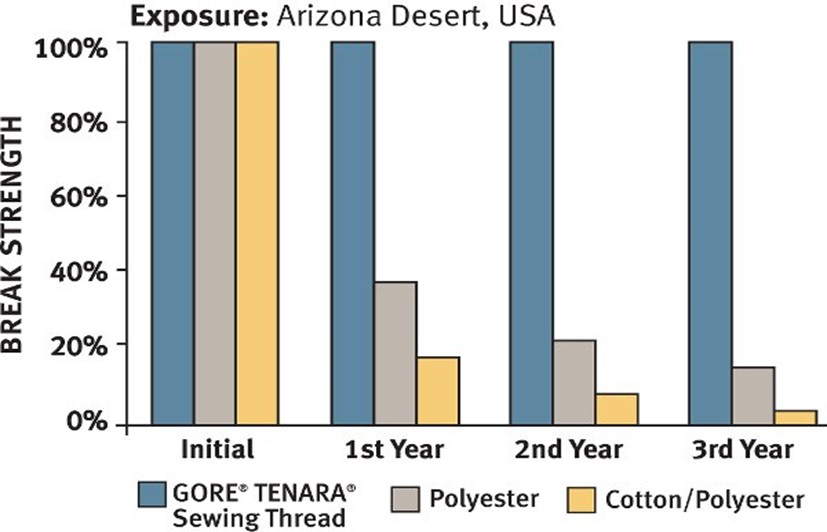

The Wind Tracker™ Windsock is constructed of outdoor grade 200 denier DuPont® nylon with Storm Tough® construction and finished with 4 rows of lock stitching at the fly end using patented high strength Gore® Tenara® thread. The applications can be in environments where water (either salt water or fresh) are present, or where corrosive chemical solutions and/or vapors are present.

The only windsock sewn with patented Gore-Tenara® thread, four stitched at the fly end for additional strength and longevity. Designed for commercial use and able to withstand harsher weather conditions over ordinary old style windsocks.

Wind Tracker™ Product Description:

The Wind Tracker™ System is designed to work in partnership with our patented pivotal harness system. The Wind Tracker™ constructed of 200 denier DuPont® nylon reinforced at the fly end with four rows of Gore Tenera® thread and lock stitched. The Wind Tracker™ can detect low wind direction and speed, increasing workplace safety. The dynamic design & international safety color is recognizable to all persons.

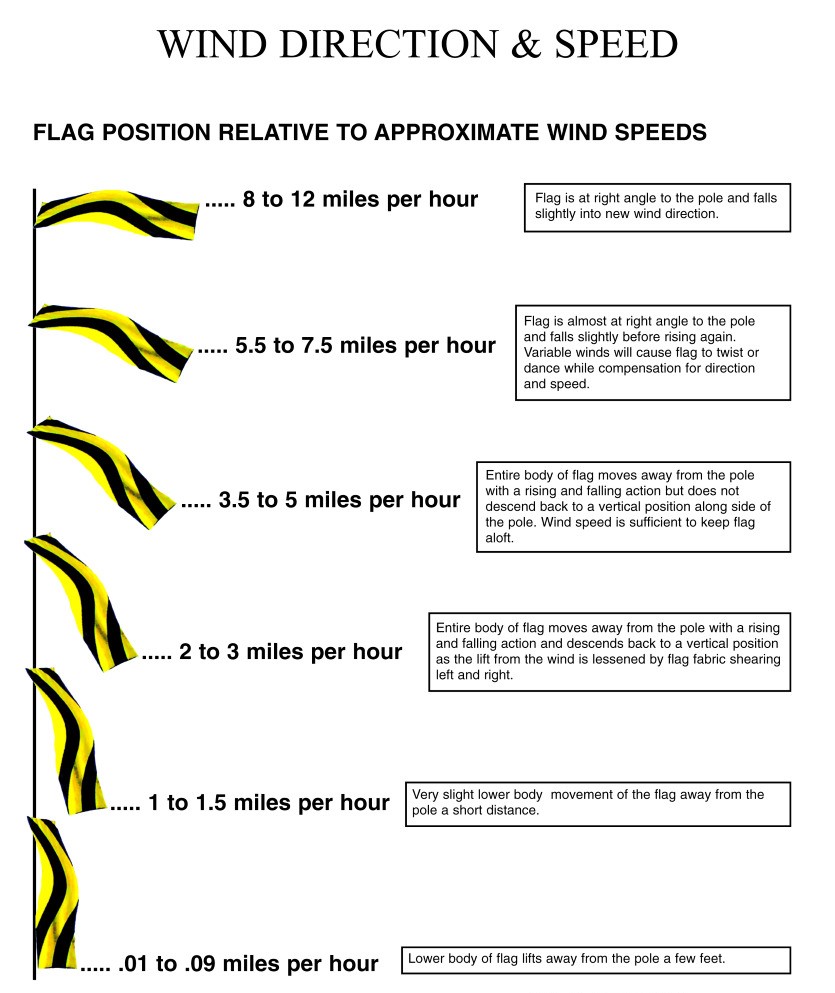

The multi-directional patented pivotal harness system animates the wind. For the first time you can “see” the wind. When air moves “against” the fabric, not through it, the Wind Tracker™ is moved in a direction relative to the force and direction of that wind. The pivotal harness system keeps the Wind Tracker™ against the wind and creates full resistance so the slightest breeze moves the Wind Tracker™. As the air currents move against and along the Wind Tracker, it rises & falls with side-to-side movement as the wind changes directions. This action insures that the Wind Tracker™ will animate the wind at any speed, and at all times.

Unique 3 Dimensional Motion: The Wind Tracker™ rises & falls as the wind changes directions. When the Wind Tracker™ attempts to “dive off”, it is pulled back into the winds force by the harness cords. This patented pivotal harness keeps the Wind Tracker™ in position and allows it to animate the wind at any speed, and at all times.

360 Degree Rotation: The patented pivotal harness rotates without the aid of ball bearings which can rust or jam. The Glide Plate rotates 360 degrees within the Glide Collar by wind force alone. This is important because there are no metal parts that require maintenance.

Rise and Fall: The Wind Tracker™ lifts the Glide Plate from the surface of the collar and rotates it with a minimal amount of surface contact. There are no mechanical parts to jam or wear out. This precise motion allows you to determine the exact windspeed at any given moment.

The harness cords allow the side-to-side tilting motion of the Wind Tracker™ which not only detects wind shear and variability of direction, but also creates an animation and visual recognition of wind variability at a glance.

Wind Tracker™ Windsock Specifications:

- Windsock Dimension: 24″ x 60″

- Windsock Material: 200 Denier all-weather nylon

- Windsock Reinforcement: 4-needle Fly Hem using Gore Tenera® thread

- Windsock Reinforcement: Lock Guard™ stitching

- Strength: Meets or exceeds commercial grade

- Harness System: Storm Tough® construction using Lexan®

- Tangle Free Rotation of the windsock system

- OSHA compliant colors

- US Patent 5,701,840

- Country of Origin: United States

- Manufacturer: FF Manufacturing, Inc

Wind Tracker 7001 Kit

Components Included:

(1) Wind Tracker™ Industry Windsock Flag

(1) Directional Vane DV9001 w/metal safety clip

(1) Pivotal Harness Plate

(1) Flip over rod w/fastener clips

(1) Lexan crossbar with (2) harness cords

(4) Wind Speed Pocket Charts

(1) Instructions

Partial list of Wind Tracker™ windsock applications:

Evacuations: Schools, Businesses, Recreational Facilities

Hazardous Materials Storage

Refineries

Golf Courses

Remote Control Airplanes

Boating & Docking

Heliports

Waste Water Treatment Plants

Government

Armed Forces

Cold Storage Facilities

Unmanned Aircraft

Waste Sites

Hang Gliding

Oil Fields

Oil Refineries

Painting: Drifting

Large Profiles Transport

Tear Gas Release In Correctional Institutions

Bomb Disposal Sites

Military Exercises

Auto Test Tracks

Jump Teams Ground Wind System

Hot Air Balloonist

Power Parachutes

Ammonia Plants For Evacuation Lanes Of Personnel

Agricultural For Drift Prevention

Small Airports

Field Burning

Portable Units For First Responders

Area Assembly

Airport Windsocks

Nuclear Power Plants

Long Range Shooting

Forestry

…and many more

Wonder Pole® Product Sheet

- Fiberglass composite

- Telescopic non-conductive fiberglass extension poles

- FR Rated: Self Extinguishing

- E84 fire retardant

- Meets or exceeds ASTM standards with UL940

- HL/UV Resistant

- ISO-9001:2000 certified

- Color Options: Diamond White or Safety Yellow

- Retracts and extends in seconds

- Mechanism: Nesting sections, transitional collars hold and grip each section

- Various sizes and heights up to 30′

- Sure Grip™ handles

- Production: United States

- Country of Origin: United States

- Storm Tough® strong

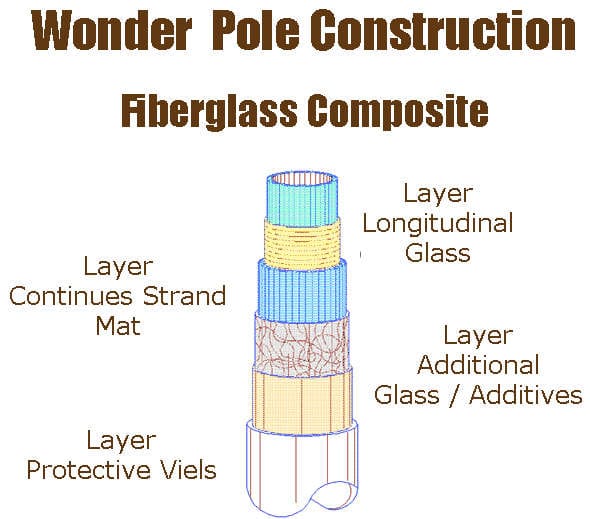

Our telescoping fiberglass Wonder Poles® are the strongest in the industry. The method of construction prohibits the line cracking of the fiberglass pole, which is common in poles with only longitudinal strands. Like a crack in your windshield, the crack will continue to grow until the pole fails. The Wonder Pole® prevents crack expansion. The high quality proprietary veils prevent fiber bloom (fiberglass slivers).

We have also added a UV inhibitor to the composition of our fiberglass. Our “Sure Grip” handle grips are factory molded and press fitted on the pole. No glue or rivets are used to hold the fittings on the pole. Wonder Pole®, they are designed for continuous use in harsh environments 24 hours a day, 365 days a year.