Ship Yards

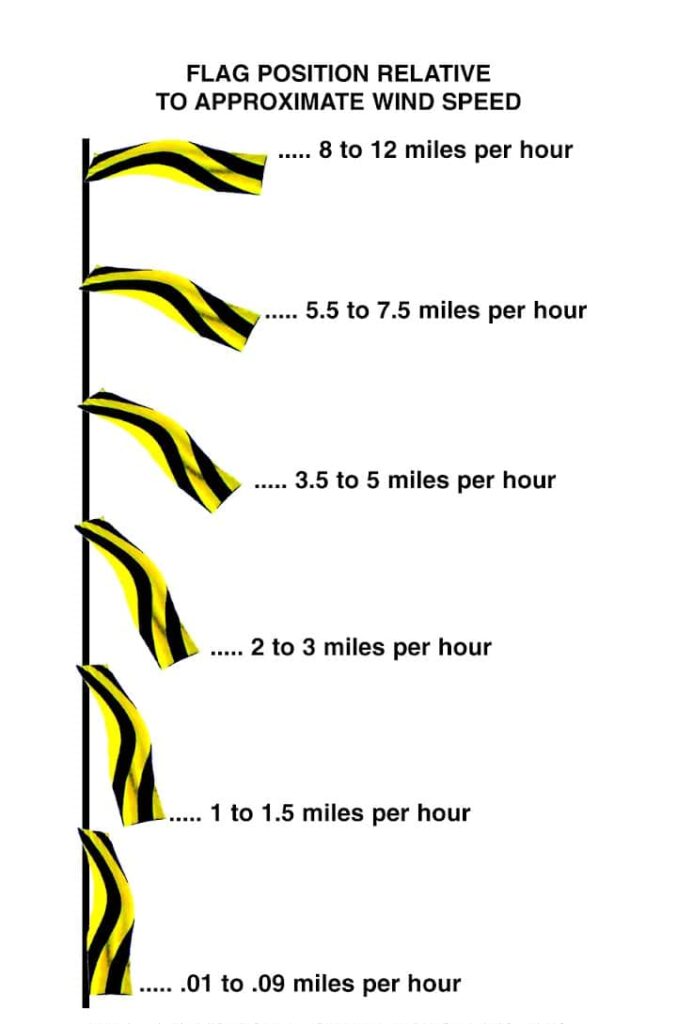

Wind Direction and Speed Monitoring:

Wind Tracker™ Windsocks provide real-time information about wind direction and speed, which is crucial for various operations at shipyards. By visually indicating the prevailing wind conditions, windsocks help personnel make informed decisions about the timing and execution of activities that are sensitive to wind, such as lifting and moving heavy loads.

Safe Crane and Lifting Operations:

Shipyards often use large cranes to lift and transport heavy components, such as ship parts and cargo containers. Wind Tracker™ Windsocks help crane operators assess wind conditions to ensure safe lifting operations. Strong winds can cause loads to sway or become unstable, posing significant risks to both personnel and equipment. Windsocks enable operators to determine if wind conditions are within safe operational limits and to take necessary precautions.

Ship Maneuvering and Docking:

Wind Tracker™ Windsocks are essential tools for ship maneuvering and docking activities. Understanding wind direction and speed helps ship pilots and docking crews manage the effects of wind on the vessel’s movement. This is particularly important in confined spaces where precise control is required to prevent collisions and ensure safe docking.

Welding and Painting Operations:

Shipyards often involve extensive welding and painting activities, which can be affected by wind conditions. Wind Tracker™ Windsocks help workers monitor wind direction and speed to avoid conditions that could disrupt these operations. For instance, strong winds can blow away welding gases, compromise weld quality, and affect the application of paints and coatings.

Emergency Response and Hazardous Material Handling:

Shipyards handle various hazardous materials, including fuels, chemicals, and paints. Windsocks play a critical role in emergency response planning and hazardous material handling. In the event of a spill or release, windsocks provide immediate information on wind direction, helping responders determine the potential spread of hazardous substances and establish safe zones and evacuation routes.

Personnel Safety and Evacuation Planning:

Wind Tracker™ Windsocks enhance overall safety by providing a clear visual indication of wind direction, which is vital for evacuation planning in case of emergencies. Knowing the wind direction allows shipyard personnel to evacuate upwind from hazardous areas, reducing exposure to harmful substances or fire.

Environmental Monitoring and Compliance:

Shipyards must comply with environmental regulations related to air quality and emissions. Wind Tracker™ Windsocks assist in monitoring the dispersion of airborne pollutants and emissions from shipyard activities. By understanding wind patterns, shipyards can implement measures to minimize the environmental impact of their operations and ensure compliance with regulatory requirements.

Fire Safety:

Fire safety is a paramount concern in shipyards due to the presence of flammable materials and ongoing welding and cutting operations. Wind Tracker™ Windsocks help fire safety teams assess wind conditions that could influence the spread of fire or smoke. This information is crucial for firefighting strategies and for establishing safe zones during fire emergencies.

Wind Tracker™ windsocks are a necessary tool at shipyards due to their role in monitoring wind direction and speed, ensuring the safety of crane and lifting operations, aiding in ship maneuvering and docking, supporting welding and painting activities, enhancing emergency response and hazardous material handling, ensuring personnel safety and effective evacuation planning, monitoring environmental impact and compliance, and improving fire safety measures. Windsocks provide essential real-time wind information that enhances the safety, efficiency, and environmental responsibility of shipyard operations.