Hydrogen Sulfide Gas – H2S

Real-Time Wind Direction Monitoring for H₂S Dispersion:

Hydrogen sulfide (H₂S) is a highly toxic, flammable, and colorless gas often found in oil, gas, and industrial processing facilities. Wind Tracker™ Windsocks provide critical real-time visual data on wind direction, which is essential for monitoring the dispersion of H₂S in the event of a release. Since H₂S gas can travel with the wind, knowing the wind direction helps facility operators and emergency responders predict where the gas may spread, enabling quick and informed decision-making.

Enhancing Safety in Case of H₂S Leaks or Releases:

H₂S is dangerous even at low concentrations, with exposure potentially leading to respiratory failure and even death in high doses. Wind Tracker™ Windsocks are indispensable for identifying the immediate downwind areas at risk of exposure during a leak or release. This allows workers to evacuate quickly and move upwind or to crosswind directions, where the risk of exposure is significantly lower, thereby minimizing the danger to personnel.

Emergency Evacuation and Response Planning:

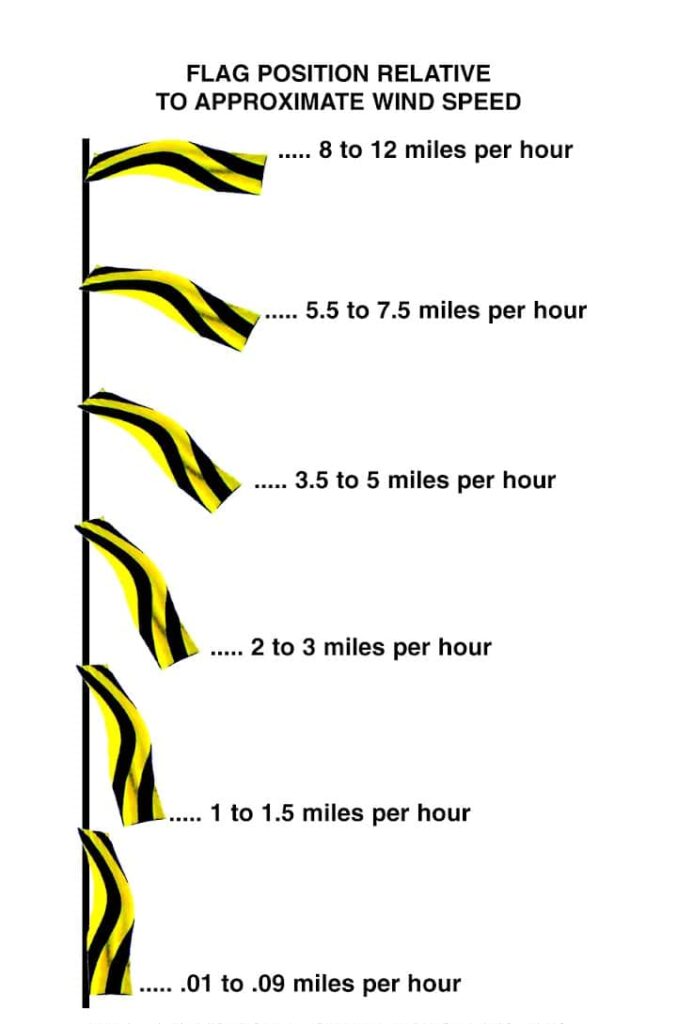

In an H₂S emergency, such as a gas leak or equipment failure, rapid evacuation is critical. Wind Tracker™ Windsocks provide immediate and clear guidance on safe evacuation routes by indicating the wind direction and speed. Workers can quickly assess which areas are downwind and potentially dangerous and which directions are safer to move toward. Emergency response teams also rely on windsocks to determine where to set up safe zones and staging areas, ensuring that personnel are kept out of hazardous zones.

Regulatory Compliance with H₂S Safety Standards:

Facilities that handle or produce H₂S gas are subject to strict regulatory standards from bodies such as OSHA (Occupational Safety and Health Administration) and the EPA (Environmental Protection Agency). Wind Tracker™ Windsocks help ensure compliance with these standards by providing a visible, reliable indicator of wind conditions, which is necessary for controlling gas dispersion and preventing unsafe exposure to workers and nearby communities. Many safety protocols and response plans require the use of windsocks to guide evacuation and shelter-in-place procedures during H₂S incidents.

Risk Management for Flammable and Toxic Properties:

In addition to being toxic, H₂S is also highly flammable. When released into the atmosphere, the gas can form explosive mixtures with air. Wind Tracker™ Windsocks are essential for managing the risk of fire or explosions by providing real-time wind data to guide decisions about the placement of fire-fighting resources, the shutdown of potential ignition sources, and the evacuation of personnel from downwind areas. Wind data helps reduce the risk of ignition and prevents the spread of toxic fumes into flammable zones.

Preventing Offsite Exposure and Environmental Contamination:

Facilities that manage H₂S must be vigilant about preventing the gas from affecting nearby communities and ecosystems. Wind Tracker™ Windsocks help monitor how wind conditions may carry H₂S offsite and inform containment and mitigation measures. By tracking the wind direction, operators can prevent hazardous concentrations of H₂S from drifting toward populated areas, natural habitats, or water sources, thus ensuring compliance with environmental regulations and protecting public health.

Air Quality Monitoring and Control:

Windsocks are used in conjunction with air quality monitoring systems to provide a comprehensive approach to managing H₂S risks. Wind Tracker™ Windsocks offer visual confirmation of wind conditions, allowing operators to correlate H₂S levels detected by sensors with wind direction and take appropriate action. This combination of tools enhances the ability to manage air quality at the facility, ensuring that H₂S concentrations remain within safe levels for both workers and the surrounding environment.

Facilitating Safe Equipment Operation and Maintenance:

Many operational tasks at H₂S-handling facilities involve the use of equipment that could inadvertently release gas into the atmosphere. Wind Tracker™ Windsocks help guide safe operating procedures by providing a visual indicator of when wind conditions are unfavorable for high-risk tasks, such as tank venting, maintenance work, or equipment inspections. If the wind is blowing toward occupied areas, operators can delay these tasks or implement additional controls to ensure safety.

Training and Emergency Preparedness:

Workers in H₂S facilities must undergo specialized training to handle the risks associated with the gas. Wind Tracker™ Windsocks play a critical role in training exercises and preparedness drills, teaching workers to interpret wind conditions and respond appropriately during emergencies. This preparedness ensures that workers know how to quickly locate upwind escape routes, use personal protective equipment, and activate alarm systems if a leak occurs.

Continuous Risk Assessment for Changing Wind Conditions:

Wind conditions can change rapidly, affecting the direction and speed of H₂S dispersion. Wind Tracker™ Windsocks provide continuous, real-time information that allows for ongoing risk assessment throughout the facility’s operations. By monitoring changing wind patterns, operators can adjust work schedules, deploy additional safety measures, or halt operations if conditions become too hazardous.

Wind Tracker™ Windsocks are a critical safety tool at facilities handling hydrogen sulfide gas (H₂S) due to their ability to provide real-time data on wind direction and speed. This information is vital for ensuring the safety of workers, guiding emergency evacuations, preventing offsite exposure, and managing the toxic and flammable risks associated with H₂S. Windsocks enhance regulatory compliance, support safe equipment operations, and play a crucial role in emergency preparedness, making them indispensable for the safe handling of this hazardous gas.