Ammonia, Chlorine, & Gas Storage

Wind Tracker™ windsocks play a crucial role in assessing wind conditions to anticipate the dispersion of hazardous gases, such as ammonia and chlorine, stored at these facilities. By monitoring wind direction and speed, facility operators can predict the potential movement of released gases, enabling them to implement appropriate safety measures to protect personnel, the facility, and nearby communities.

Emergency Response Planning:

Wind Tracker™ windsocks are integral to emergency response planning at ammonia, chlorine, and gas storage facilities. In the event of a gas leak or release, windsocks provide real-time data on wind direction, facilitating the development of effective evacuation plans, assembly areas, and response strategies. This ensures a coordinated and timely response to minimize the impact of the emergency on personnel and the surrounding environment.

Safe Operations and Maintenance:

Wind Tracker™ windsocks assist in ensuring safe operations and maintenance activities at these facilities. By precise monitoring of wind direction, operators and maintenance personnel can assess whether wind conditions are within safe limits for specific tasks, such as equipment maintenance, repair, or inspection. Windsocks provide valuable information for maintaining safe work conditions and preventing accidents related to hazardous gas exposure.

Environmental Impact Assessment:

Wind Tracker™ windsocks aid in assessing the potential environmental impact of gas releases from storage facilities. By monitoring wind direction, facility operators can evaluate how released gases may disperse in the environment, including any potential effects on air quality, ecosystems, and nearby residential areas. This information is crucial for implementing mitigation measures and minimizing environmental harm.

Regulatory Compliance:

The use of windsocks at ammonia, chlorine, and gas storage facilities is often mandated by regulatory authorities as part of safety and environmental regulations. Compliance with these regulations ensures that facilities adhere to established safety protocols and take necessary measures to protect personnel and the surrounding community from potential hazards associated with gas storage and handling.

Gas Detection System Support:

Wind Tracker™ windsocks complement gas detection systems installed at these facilities by providing real-time information on wind direction and speed. Because Wind Tracker™ windsocks do not require electricity or batteries to operate, they can serve as a fail safe tool to accompany with gas detection systems, allowing for a comprehensive approach to monitoring and managing gas-related hazards.

Public Safety Communication:

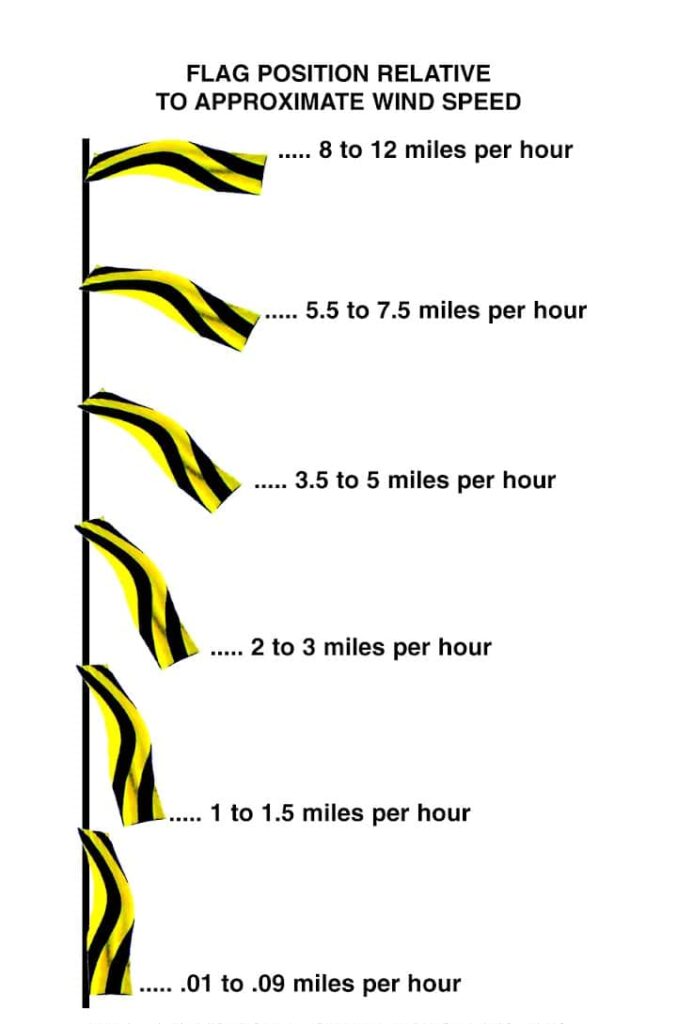

Wind Tracker™ windsocks serve as visual indicators for communicating wind conditions to facility personnel, emergency responders, and the public. The movement and orientation of windsocks convey important information about wind direction and speed, helping individuals make informed decisions regarding safety precautions, evacuation procedures, and response actions during emergencies or gas-related incidents.

Wind Tracker™ windsocks are a necessary tool at ammonia, chlorine, and gas storage facilities due to their role in assessing wind conditions, facilitating emergency response planning, ensuring safe operations and maintenance, assessing environmental impact, ensuring regulatory compliance, supporting gas detection systems, and communicating important safety information to personnel and the public. Windsocks enhance safety measures and contribute to the effective management of gas-related hazards in these industrial environments.