Crane & Heavy Equipment Worksites

Real-Time Wind Direction and Speed Awareness

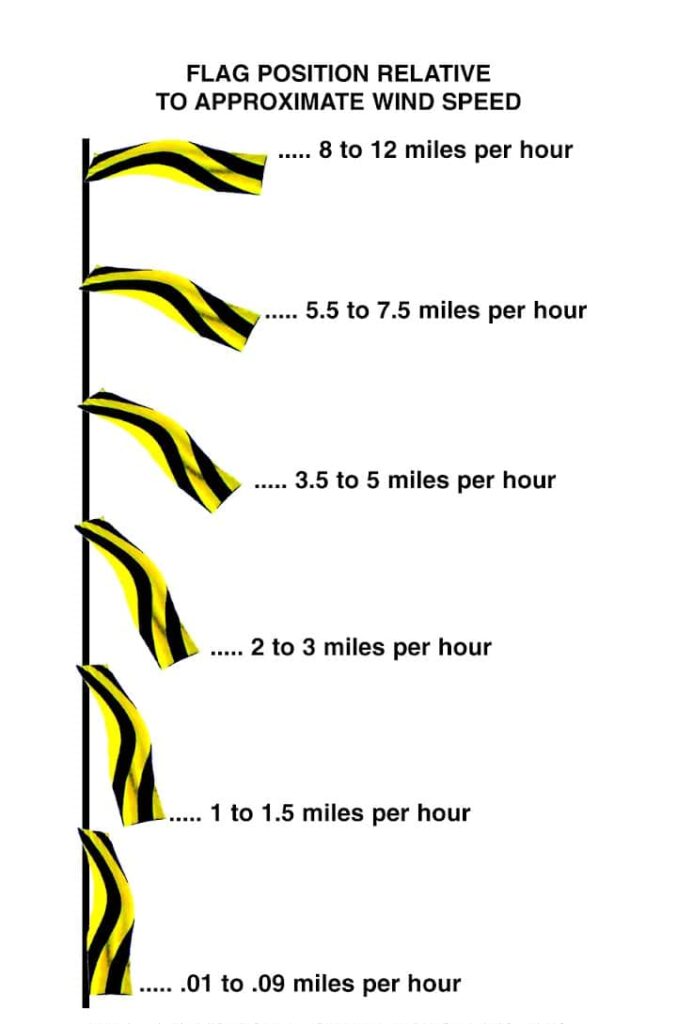

Crane and heavy equipment worksites involve lifting, hoisting, and positioning large loads where wind conditions directly affect safety and control. Wind Tracker™ Windsocks provide immediate, highly visible indication of wind direction and relative speed, allowing operators, signal persons, and site supervisors to continuously assess conditions without relying solely on electronic instruments. This real-time awareness is critical in dynamic jobsite environments where wind can change rapidly.

Safe Crane Lifting and Load Control

Wind has a significant impact on suspended loads, especially large surface-area items such as steel panels, precast concrete sections, formwork, or piping. Wind Tracker™ Windsocks help crane operators identify crosswinds and gust conditions that may cause loads to swing, rotate, or become unstable. By clearly showing wind behavior, windsocks support safer lift planning and help determine when lifting operations must be paused to prevent accidents or equipment damage.

Operator and Ground Crew Safety

Heavy equipment worksites require close coordination between operators and ground personnel. Wind Tracker™ Windsocks provide a common visual reference that helps crews anticipate wind-driven hazards such as dust clouds, debris movement, or reduced visibility. This shared awareness improves communication and reduces the risk of workers entering unsafe zones during active lifting or material handling operations.

Support for Critical Lift Planning

Critical lifts require strict environmental controls due to their complexity and risk level. Wind Tracker™ Windsocks play an important role in pre-lift assessments by confirming wind conditions at the lift location, which may differ from nearby weather reports. Continuous visual monitoring during the lift ensures conditions remain within approved limits throughout the operation.

Dust, Debris, and Visibility Management

Construction and earthmoving activities often generate dust and airborne debris that can impair visibility and create respiratory hazards. Wind Tracker™ Windsocks help crews identify downwind areas so dust suppression measures can be applied effectively and equipment movement can be adjusted to maintain safe working conditions.

Emergency Response and Evacuation Guidance

In the event of an emergency such as equipment failure, fire, or hazardous material release, knowing wind direction is essential for determining safe evacuation routes and assembly areas. Wind Tracker™ Windsocks provide instant visual guidance that remains effective even if power, communications, or electronic monitoring systems fail.

Durable, Low-Maintenance Jobsite Reliability

Crane and heavy equipment worksites are often temporary and exposed to harsh conditions. Wind Tracker™ Windsocks are rugged, require no power, and need minimal maintenance, making them ideal for both short-term and long-term projects. Their passive operation ensures continuous wind awareness regardless of site infrastructure or power availability.

Wind Tracker™ Windsocks are a critical safety tool at crane and heavy equipment worksites. They enhance lift safety, improve coordination between operators and ground crews, support critical lift planning, and provide reliable wind awareness for emergency response. Their simplicity, durability, and constant visibility make windsocks an essential component of safe and compliant heavy equipment operations.