Resources

Wind Tracker™

The windsock system that will help protect your interests and minimize your exposure to liability.

Windsock Implementation:

Where should we install our windsocks?

Ensuring the safety of workers during emergency evacuations hinges on the careful selection of the installation location and height for Wind Tracker™ windsocks.

For use by personnel on site the key factors are line of sight, and the primary location of a possible incident in relationship to the designated areas of reasonable safety. In other words, “Where did it happen, where am I going to go, and can I see the wind on the way”.

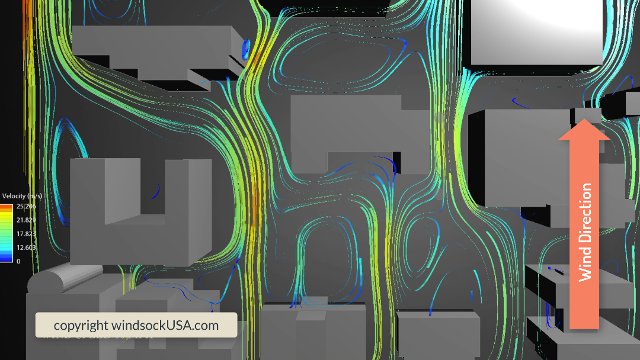

Positioning the windsock in a location with unobstructed visibility is crucial. This ensures that emergency responders and workers can quickly and accurately assess wind conditions, aiding in decision-making during evacuations. Placing the windsock in a clear line of sight from evacuation points enhances its effectiveness.

Take into account the designated evacuation routes and areas where workers gather during emergency situations. Installing wind measurement devices along these routes provides real-time information on wind direction and speed, aiding in the safe navigation of evacuees away from potential hazards.

What height should we install our windsocks?

The Wind Tracker™ System should be installed within the routes of evacuation and at a height not to exceed 30 feet (10 meters) above grade for proper performance, safety, and accuracy.

A commonly suggested mounting height for windsocks is around 10 feet (3 meters) above grade. This standard height is often utilized in aviation settings and aligns with regulations for consistent wind reporting at airports.

Our research shows 15-18 feet above grade to be the most effective height for monitoring wind movement and speed near or around buildings and structures.

Installing the Wind Tracker™ Windsock System at high elevation where unobstructed wind conditions prevail will not demonstrate the actual wind movements in, and around the area of evacuation, and may lead to persons exiting the site or area in the wrong direction.

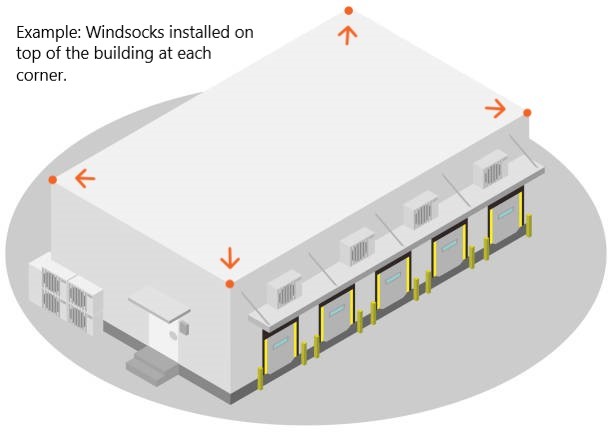

How many windsocks should we use at our location?

One windsock should be visible by workers when using an exit. The Wind Tracker™ can be seen up to 1/4 mile away, however obstructions along the evacuation route may necessitate the need for one or more additional windsocks.

For inbound traffic such as helicopters, and first responders one or two elevated windsocks may be all that is required. They should be visible from the air taking into consideration the approach.

Additional Things to consider:

Redundancy and Reliability: Consider installing multiple windsocks at different locations within the facility to provide redundancy and ensure reliability. This redundancy helps mitigate the risk of device failure and ensures that wind information is available from various vantage points, enhancing overall safety during evacuations.

Integration with Emergency Protocols: Align the installation with established emergency protocols and procedures. Ensure that wind information from the devices is integrated into the facility’s emergency response system, allowing for seamless communication and coordination during evacuations.

Training and Awareness: Educate workers and emergency responders about the significance of windsocks in the evacuation process. Promote awareness of how wind conditions can impact safety and provide training on interpreting the information provided by these devices.

OSHA (Appendix C to 1910.119) Compliance Guidelines and Recommendations for Process Safety Management states: “Unwanted incidental releases of highly hazardous chemicals in the process area must be addressed by the employer as to what actions employees are to take. If the employer wants employees to evacuate the area, then the emergency action plan will be activated.

For outdoor processes where wind direction is important for selecting the safe route to a refuge area, the employer should place a wind direction indicator such as a windsock at the highest point that can be seen throughout the process area. Employees can move in the direction of cross wind to upwind to gain safe access to the refuge area by knowing the wind direction.”

Technical Resources:

Windsock Applications:

Industrial & Hazardous Material Handling

- Oil Refineries

- Chemical Plants

- Gas Storage Facilities

- Ammonia & Chlorine Storage Sites

- Waste Treatment Plants

- Landfills & Waste Disposal Sites

- Pipeline Companies

- Hydrogen Sulfide (H₂S) Handling Facilities

- Refineries

- Cold Storage Facilities

- Oil Fields

Aviation & Airfields

- Airports (Commercial & Private)

- Heliports & Helipads

- Hot Air Balloon Launch Sites

- Hang Gliding & Paragliding Zones

- Remote-Controlled (RC) Airplane Fields

- Military Airfields & Training Grounds

- Smoke Jumpers

- RC Airplanes

Emergency Response & Safety

- Fire Departments & Fire Training Centers

- First Responder Stations

- Bomb Disposal Sites

- Emergency Assembly Areas

- Disaster Relief & Emergency Management Centers

- Emergency Evacuation Plan

- OSHA Color Coding

Maritime & Water-Based Industries

- Shipyards

- Boating Docks & Marinas

- Offshore Drilling Platforms

- Coast Guard Stations

- Ferry Terminals

- Fishing Ports

Agriculture & Environmental Management

- Crop Dusting & Agricultural Spraying Areas

- Controlled Field Burning Zones

- Weather Monitoring Stations

- Forestry & Wildfire Management

Correctional & Government Facilities

- Correctional Institutions

- Military Bases & Training Facilities

- Border Patrol Stations

- Law Enforcement Training Centers

Construction & Heavy Equipment Operations

- Crane & Heavy Equipment Worksites

- Wind Turbine Construction Zones

- Bridge & Highway Construction Sites

- Industrial Demolition Sites

Recreational & Outdoor Sports

- Golf Courses

- Parachuting & Skydiving Centers

- Power Parachute & Ultralight Aircraft Fields

- Sports Stadiums & Open-Air Arenas

- Kite Surfing & Windsurfing Locations

- Shooting Ranges

Railway & Transportation Infrastructure

- Railway Yards & Freight Terminals

- Trucking Depots & Logistics Centers

- Highway Rest Stops with Fueling Stations

Waste Management & Hazardous Material Disposal

- Nuclear Power Plants & Radioactive Waste Sites

- Industrial Waste Incinerators

- Hazardous Material Transport & Storage Facilities

- Waste Water Treatment Plants